With the van insulated with silver bubble wrap,and the carcasses of bench set/bed and kitchen cupboards prefabricated,but not fixed in place,it was time for the van's first trip to Jason at Clutton.

Tasks-

Air Heater

-to fit to the floor a Propex 2000e air heater,which runs on both propane,or 240 v electricity(not both at the same time !)This needs air intake and exhaust pipes fitting through the floor to the outside.It blows ducted hot air into the van living area.

Tasks-

Air Heater

-to fit to the floor a Propex 2000e air heater,which runs on both propane,or 240 v electricity(not both at the same time !)This needs air intake and exhaust pipes fitting through the floor to the outside.It blows ducted hot air into the van living area.

propex 2000e space heater

propex 2000e space heater Gas system

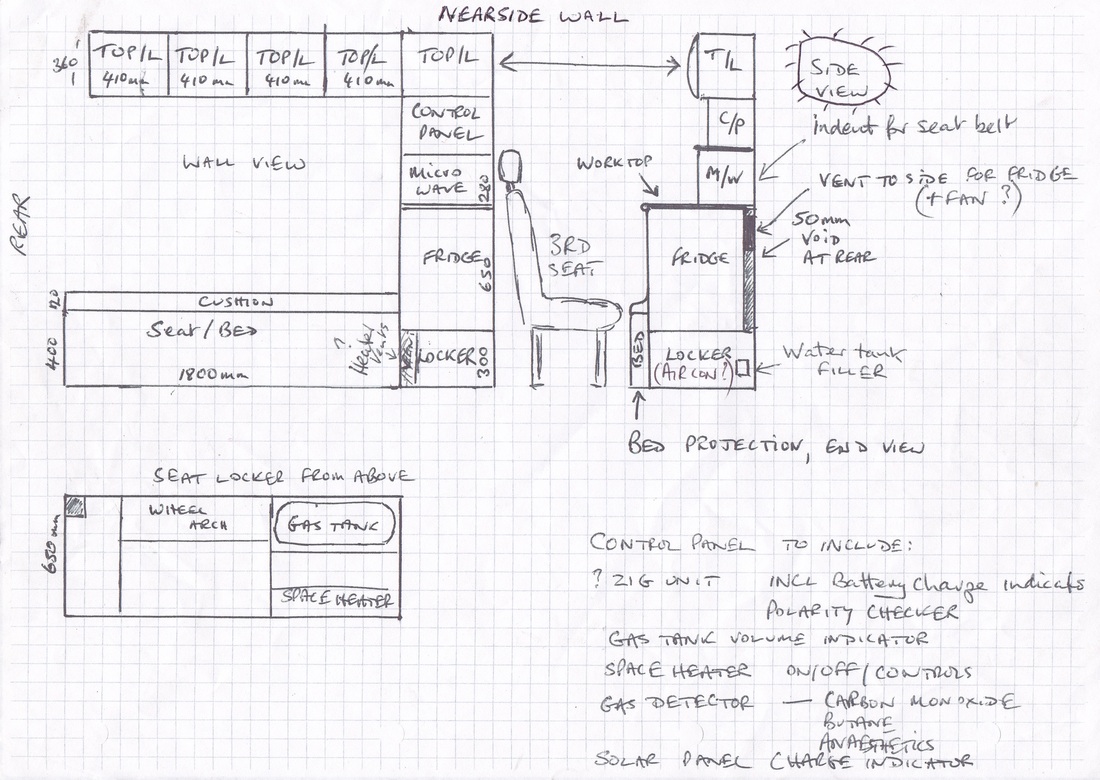

-to install a bulk propane tank inside the van,with a filling point in an inconspicuous place outside the van.

This can be filled up at LPG pumps at fuel stations,and a 30 Litre fill should last up to six weeks,according to accounts.Gas will be used to run the air heater,the water heater,and the cooker hob,although connecting up will come later.

Electrical system

Fit the wiring to install the following:-

-Leisure batteries(additional batteries to run 12v electrical equipment,fridge,LED lighting,water pump,toilet flush etc)

-240 v Hook up(to connect to mains power on campsites and halts)and to run the electrical parts of the air heater,and hot water heater.extra sockets will allow charging of equipment(although also possible through 12 Volt sockets )and to run the microwave

-Wiring for all of this(12 Volt and 240 Volt systems)

-To run all of this ,an ECU(Electrical Control Unit)is needed,with 12v fuses on the circuits,circuit breakers on the 240 system

-wiring to include coaxial cable for TV/satellite

The wiring will eventually be hidden by refitting the plywood panels,ply-lining the ceiling,and by the furniture.

Fit solar panels on the roof to provide auxiliary charging for leisure batteries(these are otherwise charged via the ECU by the van alternator when driving,and the 240 V hook up if connected at a campsite.)Solar panels will provide some versatility,and allow free camping for a weekend or so without need to connect up to external power.In particular,,having opted for a 12 V compressor fridge,this will be running all the time ,needing a constant trickle of 12 current.

Skylights

Being wary of cutting holes in my van at this stage,I have asked Jason to fit 2 small skylights,one for the living area,one for the bathroom,With security in mind,these will be small,30 cm squared,and will not allow entry if they are prised off.The will provide a little light,but are chiefly with ventilation in mind

Water system

to fit an 80 L fresh water tank,slung under the van(CAK tanks ,that source of everything known to man for the camper convertor,do a bespoke one for Renault Masters) and a small waste water tank

RSS Feed

RSS Feed